Street Source is shutting down April 30th, 2026. Read the announcement

H

Turbo question

A

anguswilly

+1y

Seriously, if you actually try it you'll be surprised how easy the pushing is, you don't need to hit it very hard, you can do it rally easy, if anything you can try it first and if it fails you can still drill it and JB weld - but be advised, I have seen (and repaired them) people try it and it cracks and leaks.

B

b52fighter

+1y

Ill have to think about it some more, you wouldn't happen to know how big of a punch if have to get? Our a tap for a -10AN line, I'm gonna be running a t3/t4 turbo

A

anguswilly

+1y

If tapping the pan (and actually only the block) You want a 3/8 npt to -10AN fitting.

If tapping the pan what you need is a 3/4" tapered punch (you can cut the length down to suit your location in the truck/car) what is important is how you grind the tip - here is what you need.

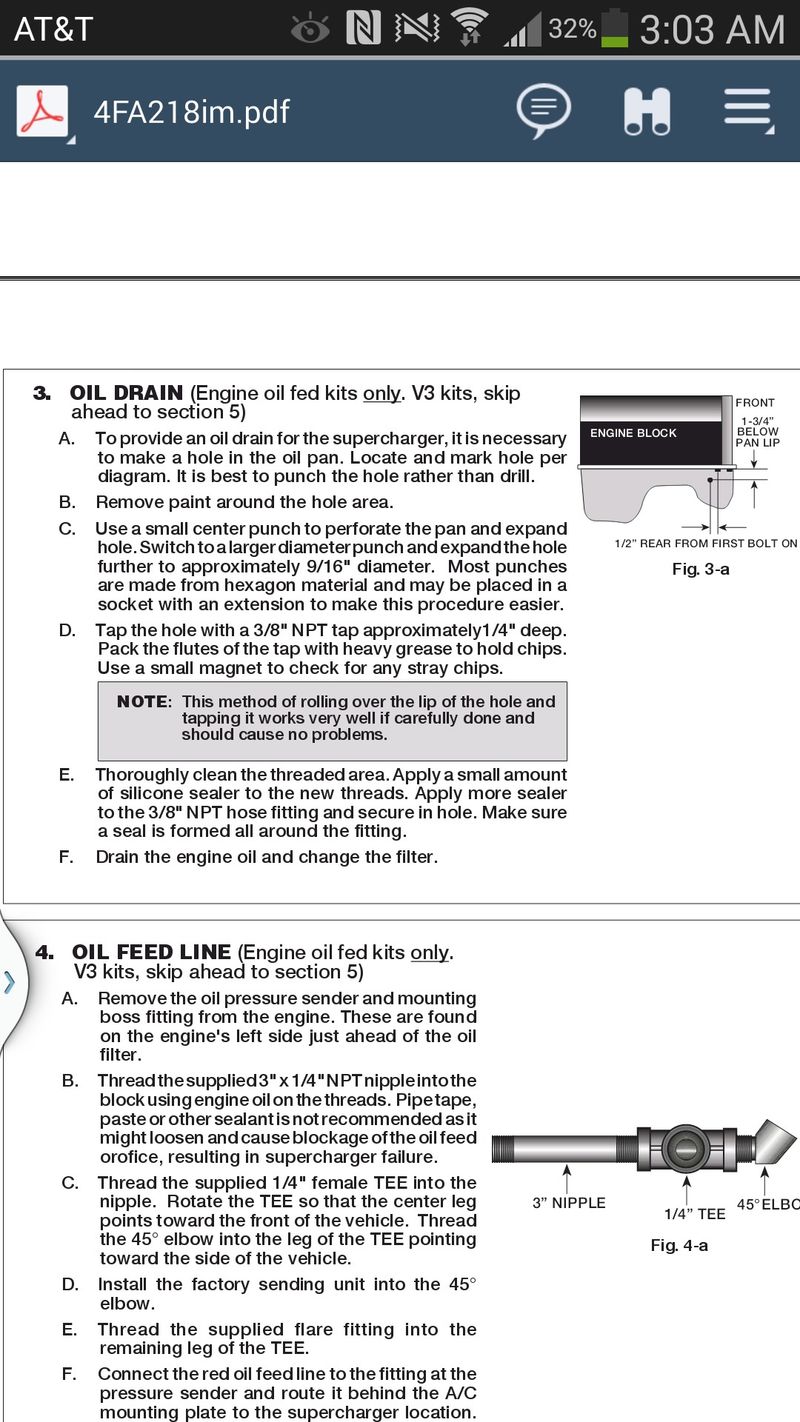

Use a small center punch to perforate the pan and expand hole. Switch to a larger diameter punch and expand the hole further to approximately 9/16" diameter. Most punches are made from hexagon material and may be placed in a socket with an extension which you can hit with a hammer to make this procedure easier.

use a 3/4" punch that has the end ground to a point so that from the tip to the part where it is 9/16" in diameter, the length is only 3/4 to 1", this way when you punch the hole to 9/16" there will only be 3/4" or so of the punch protruding into the pan.

Tap the hole with a 3/8" NPT tap approximately1/4" deep (just enough to start the threads). Pack the flutes of the tap with heavy grease to hold chips. Use a small magnet to check for any stray chips.

Thoroughly clean the threaded area. Apply a small amount of silicone sealer to the new threads. Apply more sealer to the 3/8" NPT hose fitting and secure in hole. Make sure a seal is formed all around the fitting.

Drain the engine oil and change the filter.

These are the instructions that I include with my turbo kits and I have never had a customer who has had an issue.

B

b52fighter

+1y

Correct me if I'm wrong, but 9/16 dia. for a 3/8s tap? 9/16 is approx. .435, and 3/8s is .375, when doing npt you wanna go slightly smaller then the recommended drill size for a standard tap, what I learned in school I'd you want about 75% thread contact

B

b52fighter

+1y

I guess that's what they say in the vortech instructions, I guess I'm thinking to hard.

A

anguswilly

+1y

Yes, 9/16" is the correct size for a 3/8 NPT tap - 3/8 NPT threads are much larger than 3/8"

A

anguswilly

+1y

And YES - the vortech instructions are the best way!

B

b52fighter

+1y

My bad, I don't have my charts with me, seems easy enough, might have to give it a shot

A

anguswilly

+1y

What engine is it?

B

b52fighter

+1y

2.2

Related Discussions in Mazda Engine Performance

Thread

Posts

Last Post