I think I screwed up =(

itslikewhooa

+1y

yeah helped out a lot and I think I'm gonna go that way too... unless when i look at the truck this weekend, and realize i just over looked something and its all together fine.... but i really don't think it is lol but I can hope!

immortal1 (linn)

+1y

Good luck with the repairs / redesign. Just my .02 (and Geoff knows what I am talking about) body work SUCKS. I would be much happier building a new frame vs having to do bodywork like moving a wheel opening forward. On the other hand, IF you did relocate the wheel well (and did a good job at it) it would be a unique setup. But then again if anything happened to the bed of the truck you could not just put on another bed. Eitherway, hope things work out.

itslikewhooa

+1y

didn't really ever think of the possibility of something happening to the bed.. but that's a great point lol I'm leaning towards going with changing the rear section of frame..... the shitty part is, its only forward by maybe 3/4 of an inch

speedster93b

+1y

u mean geoff me? lol

yeah man it be way easier to remake the frame then cut apart your bed. that would really suck.

itslikewhooa

+1y

ok so I'm gonna take every ones advice and go with fixing the notch.... because I guess I would be an idiot if i didn't listen to everyone lol

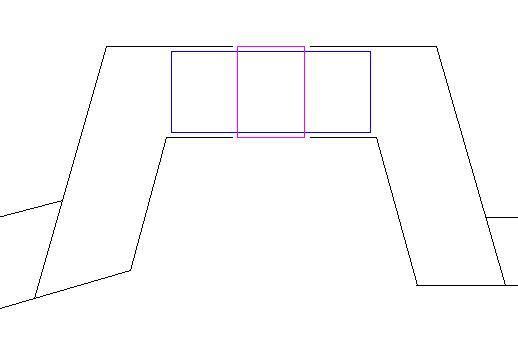

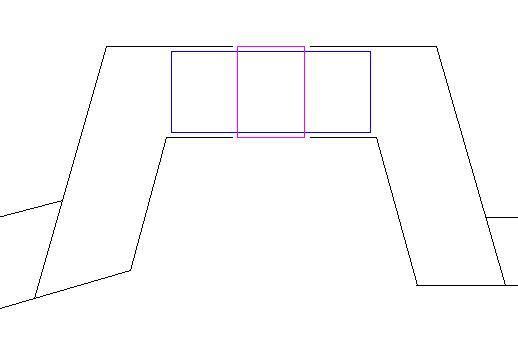

what I think I'm going to do is cut the middle of the notch (red line), and have a piece of tube steel bent up to fit tightly inside of the "old" notch so that i can stretch it the distance I need to to make everything work(blue square). then weld the two pieces of the "old" notch to the smaller tube inside, then make up some small pieces to fit in the "gap" between the two "old" notch pieces and weld those in for a cosmetic look (purple square) and then grind everything down so you cant tell I ever had to cut it..... =) between the smaller tube the individual pieces and the bag bracket all getting welding in there i think that it should still be structurally strong enough to support the air setup and abuse it will take.

what I think I'm going to do is cut the middle of the notch (red line), and have a piece of tube steel bent up to fit tightly inside of the "old" notch so that i can stretch it the distance I need to to make everything work(blue square). then weld the two pieces of the "old" notch to the smaller tube inside, then make up some small pieces to fit in the "gap" between the two "old" notch pieces and weld those in for a cosmetic look (purple square) and then grind everything down so you cant tell I ever had to cut it..... =) between the smaller tube the individual pieces and the bag bracket all getting welding in there i think that it should still be structurally strong enough to support the air setup and abuse it will take.

speedster93b

+1y

dude. just cut out the notch and re-make it. don't hack it back together.

S

snoplow

+1y

cut it apart, use piece of flat and extend then weld it back together. plate it up. i think you are over thinking it at this point. sometimes simpler is more better.

mazdamandan

+1y

unibody would fix it if you only need a little bit, but for sake of proportions I would def not move the wheel wells although I believe ya could pull it off bodywork wise.

Are ya doing bag over axle or bag over bar?

I would cut off the back end by grinding out the welds ya put in the front of the c notch, and redo the back half in new steel, and round out the rear of the frame , do something sic with it, anyways GL!!

pics pics pics!!

Are ya doing bag over axle or bag over bar?

I would cut off the back end by grinding out the welds ya put in the front of the c notch, and redo the back half in new steel, and round out the rear of the frame , do something sic with it, anyways GL!!

pics pics pics!!

immortal1 (linn)

+1y

Yep, you be the one LOL.

Related Discussions in General Discussion

Thread

Posts

Last Post

7

last post by

Babyfartzmageezaks530 +1y

5

A

last post by

Alreadyhavingissues +1y