Street Source is shutting down April 30th, 2026. Read the announcement

The Fat Girl 86', C30, 3+3, dually, bagged, SFBDed on 22.5"s

90338 views

193 replies

33 following

The Fat Girl 86', C30, 3+3, dually, bagged, SFBDed on 22.5"s

john-e bravada

+1y

Well it looks like it's going to work! I spun a junk rim last night to see if I could reach the beadseats and it looks like I can. 6 to go:)

75dually

+1y

Steve, How thin did you have to make the backside of the rim? I know you can take out quite a bit out of the front of the rim, but it is that backside that I am worried about. Also how much would you charge to do a set of 8? Please let me know.

john-e bravada

+1y

You're not going to like it. $200 more then Trevor charges. I did my own because I'm cheap, I'm not in the business. Trevor's the expert have him do it! I barley have time to build my own stuff.

john-e bravada

+1y

Made some progress last night, got the front clip torn apart and the Dodge RAD mounted. The CAC looks like it will fit if I hack out the core support stiffening braces. I'll have to make some cool ones to put out wider to strengthen it back up. Getting the AC condensor back it will be a treat. I'm thinking about using the dodge condensor and AC pump with the rest of the Chevy system. Has anyone mixed and matched AC components before?

Also checked the front axle centerline with the 1" forward Z and stretched arms. Looks like the front wheels will be centered @ full up and an inch back slammed, close enough! I proceeded to finish the Z in the front. I still want to mock up the core support and fenders to know everything came out right before I gusset and plate it.

Also checked the front axle centerline with the 1" forward Z and stretched arms. Looks like the front wheels will be centered @ full up and an inch back slammed, close enough! I proceeded to finish the Z in the front. I still want to mock up the core support and fenders to know everything came out right before I gusset and plate it.

BB

big bear

+1y

hell yes

john-e bravada

+1y

Thanks Big Bear, good to know someones watching:)

Well after a week off for the eye doctor to dig all the rusty metal out of my eye, I can't stand it any more, I'm going back out to the shop!

In the mean time my tires came in and I mounted one up on my mock up rim, the hard way! Mounting 40 series rubber with spoons SUCKS! I was surprised with the rims being over turned the tire aired up fine. I guess I need to get back into the machine shop and turn the 6 good ones.

Well after a week off for the eye doctor to dig all the rusty metal out of my eye, I can't stand it any more, I'm going back out to the shop!

In the mean time my tires came in and I mounted one up on my mock up rim, the hard way! Mounting 40 series rubber with spoons SUCKS! I was surprised with the rims being over turned the tire aired up fine. I guess I need to get back into the machine shop and turn the 6 good ones.

john-e bravada

+1y

I got a lead on another Cummins truck donor last week so Friday I decided to take a handfull of cash and go take a look.... now I have some more yard art!

It's a 91' non-intercooled CTD with the 3 speed non lockup auto trans. I'm probably still going to run my 91.5' intercooled motor but now I have options and a running example for the swap. I'm guessing whatever I don't use will be up for sale in the end.

It's a 91' non-intercooled CTD with the 3 speed non lockup auto trans. I'm probably still going to run my 91.5' intercooled motor but now I have options and a running example for the swap. I'm guessing whatever I don't use will be up for sale in the end.

D

dragnframe2000

+1y

Trust me, there's a lot of people watching. Keep up the good work. Everybody loves pics of the progress

john-e bravada

+1y

Thanks Dragn, sometime you feel like your talking to the wall:)

After 2 nights of cutting, prying and beating the drivetrain is in..... This trans is HUGE!

I had to completely remove the heater box and cut the firewall up 3"+, the gas pedal will have to move over a bunch and the driveshaft is going to need a serious tunnel. I have allot of sheet metal work to do to the floor...

After 2 nights of cutting, prying and beating the drivetrain is in..... This trans is HUGE!

I had to completely remove the heater box and cut the firewall up 3"+, the gas pedal will have to move over a bunch and the driveshaft is going to need a serious tunnel. I have allot of sheet metal work to do to the floor...

john-e bravada

+1y

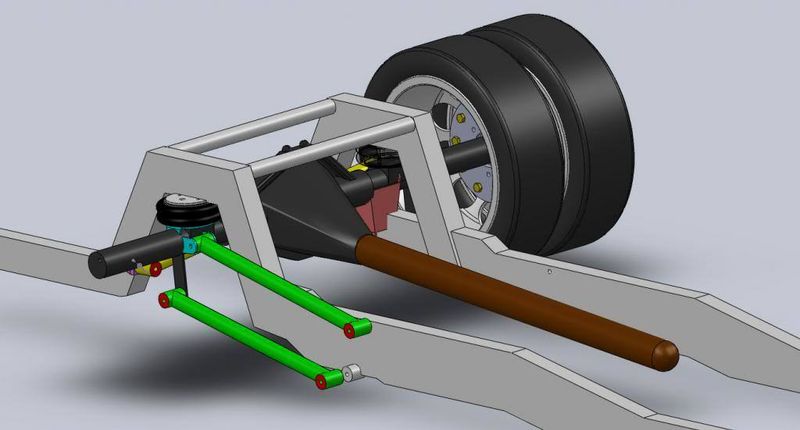

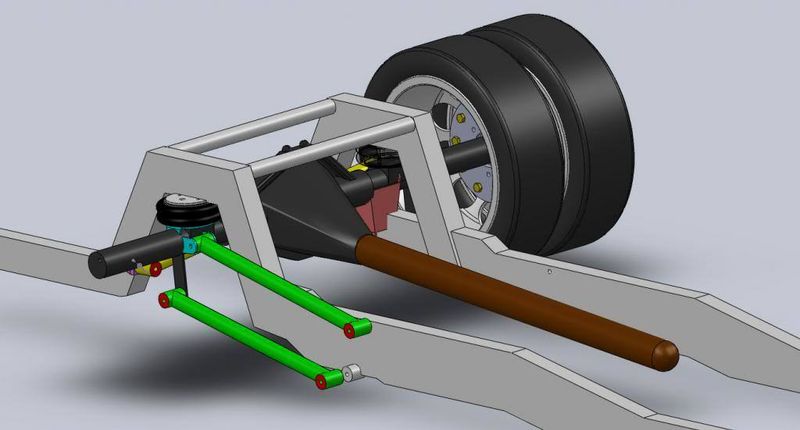

I've been slowly knocking off some of the little things; once the trany and engine mounts were done I measured the output yoke angle. With that I could finally get back to the rear suspension. I fab'ed upper and lower bag mounts and hung the axle from them to fab the suspension.

With the full compression height and pinion angle set I swapped the SRW hubs for DRW hubs to narrow the 14B to a C&C width.

With my adapter and mock up wheel mounted I found I don't have much room to run the 4-link between the frame and tire.

So I started fabbing the parallel 4-link. The links are 30" long with about 7" of vertical separation. Once the links are in I'll make the track bar as long as possible to limit the side to side shift from lift to drop. I calculated a 33" bar would give me 3/8" of side shift so with a 40"+ bar I should even better off. It looks good on paper.

I managed to get the links all tacked up and the uppers brackets set, on to the lowers.

With the full compression height and pinion angle set I swapped the SRW hubs for DRW hubs to narrow the 14B to a C&C width.

With my adapter and mock up wheel mounted I found I don't have much room to run the 4-link between the frame and tire.

So I started fabbing the parallel 4-link. The links are 30" long with about 7" of vertical separation. Once the links are in I'll make the track bar as long as possible to limit the side to side shift from lift to drop. I calculated a 33" bar would give me 3/8" of side shift so with a 40"+ bar I should even better off. It looks good on paper.

I managed to get the links all tacked up and the uppers brackets set, on to the lowers.