A

valves

P

periportfd

+1y

I'm not sure what valve that is, but I would assume "cyl" stands for pneumatic cylinder not compressed gas cylinder. Most direct acting valves are used for positioning cylinders ect. in process control. I'd hook up the "cyl" to a "T" in the bag line and "exh" to atmosphere. Maybe include the manufacture and part #.

P

periportfd

+1y

Heres a link for some reading and diagrams.

http://www.omega.ca/techref/techprinc.html

http://www.omega.ca/techref/techprinc.html

S

s10soolow

+1y

they say haldex 3704

valve number 90054075

oriface 3/32 * 1/16

volts 12 vcd

mopd 100

watts 10

another one I have says

tectran

p/n 80-1075ss

12 v.d.c. 130psi

105 amp

valve number 90054075

oriface 3/32 * 1/16

volts 12 vcd

mopd 100

watts 10

another one I have says

tectran

p/n 80-1075ss

12 v.d.c. 130psi

105 amp

P

periportfd

+1y

The Haldex part # you gave is for a normally open soleniod valve. The Tectran 80-1075ss is listed as a normally open 12v soleniod valve with (3) 1/4" ports. There is a 80-1074ss listed as normally closed (which is what you need) but still the wrong configuration. You can probably run both valves hooked up incorrectly but the flow paths will not run as designed. These valves are for semi truck air brakes so would probably be pretty reliable. The problem is you are using them for your primary valves which they aren't designed for. They are meant to control the secondary, working valve. So they are basically switches. I'd suggest getting some normally closed, tried and true valves....Parker in my opinion.

S

s10soolow

+1y

the truck trore i bought them at told me these are the only ones they cary they do not have the normaly closed. But you said I can use the ones I have? will they work properly? they seem to work in my house hooked to a bag and compresor. But if they dont I guess il have to trie and maybe exchange them!!!! I hope!!!!

P

periportfd

+1y

Edited: 12/29/2005 1:22:11 PM by periportfd

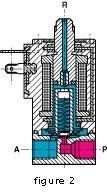

I would unplug the top port and blow threw each port to "map your valve" once you know which ports are constantly flowing when the valve isn't energized (ports R and A in this picture)then you can leave those ports open for exhaust. Then find the port that is normally closed or isolated (port P in the picture)and hook it to the "t" for the dump line. Im not completely sure how your particular valve will function hooked up like this, but I would suggest keeping R and A open not plugged with either a filter or silencer to keep crap out. The reason I suggest this is it may turn out the plunger can't return or open smoothly if it creates pressure or vaccum behind it when the top port is plugged. When you use these valves as fill valves there may be a problem if what Im saying happens to be true since you will have to plug one of them. These are just some things to consider if you decide to use them. I haven't seen them personally so wouldn't suggest taking this advice as golden and run with it. It's ultimately the safety of your ride so I still suggest getting some 2 way valves. For the size you are using, some direct acting, normally closed, 2 way valves wouldn't be to pricey. Good luck!

I would unplug the top port and blow threw each port to "map your valve" once you know which ports are constantly flowing when the valve isn't energized (ports R and A in this picture)then you can leave those ports open for exhaust. Then find the port that is normally closed or isolated (port P in the picture)and hook it to the "t" for the dump line. Im not completely sure how your particular valve will function hooked up like this, but I would suggest keeping R and A open not plugged with either a filter or silencer to keep crap out. The reason I suggest this is it may turn out the plunger can't return or open smoothly if it creates pressure or vaccum behind it when the top port is plugged. When you use these valves as fill valves there may be a problem if what Im saying happens to be true since you will have to plug one of them. These are just some things to consider if you decide to use them. I haven't seen them personally so wouldn't suggest taking this advice as golden and run with it. It's ultimately the safety of your ride so I still suggest getting some 2 way valves. For the size you are using, some direct acting, normally closed, 2 way valves wouldn't be to pricey. Good luck!

S

s10soolow

+1y

so i can or cant?

P

periportfd

+1y

Edited: 12/29/2005 1:33:50 PM by periportfd

I would say it's a bad idea. The other thing I forgot to mention is if you hook it up the way I'm suggesting, the spring is the only thing holding the pressure in. That's why I'm saying it's not designed to be hooked up that way. The pressure in port A is also pushing down on the poppet when it's not energized. Depending on the specs of that valve the spring may not be able to hold the pressure by itself. I guess for that reason it would be better to hookup the "t" to port "a" and use the port "p" for exhaust but then the port "r" has to be plugged.

I would say it's a bad idea. The other thing I forgot to mention is if you hook it up the way I'm suggesting, the spring is the only thing holding the pressure in. That's why I'm saying it's not designed to be hooked up that way. The pressure in port A is also pushing down on the poppet when it's not energized. Depending on the specs of that valve the spring may not be able to hold the pressure by itself. I guess for that reason it would be better to hookup the "t" to port "a" and use the port "p" for exhaust but then the port "r" has to be plugged.

P

periportfd

+1y

Ya know, that's probably why your valve is leaking on the dump side. The spring isn't strong enough to hold it without pressure on the opposite side to help. So I guess the only way is hooked up with A.

P

periportfd

+1y

I got an idea. Try hooking up the Port "A" directly to your bag. Hookup port "R" to your fill valve. Leave port "P" open to exhaust. Then when its not energized it allows your fill valve to flow to the bag and when you energize it the bag pressure will release out "P" and you don't need a "T" anymore.

Related Discussions in Air Ride Suspensions

Thread

Posts

Last Post