front sway bar??

2246 views

22 replies

7 following

S

front sway bar??

3

3rdtimesacharm

+1y

im getting ready to start to bag my mazda tomorrow i was wondering what do you do with the sway bar in the front eliminate it?

thebeaumartin

+1y

yea stick it in the trash but you must have 2 valves per bag to keep the air from transfering back and forth while cornering.

V

v8mazda4ever

+1y

yes eliminate it it just gets in the way when placing your bag and will bind up when slamming it on the ground. If you are running 8 valves then each bag is self contained and you do not need the sway bar.

3

3rdtimesacharm

+1y

im just doing the front tomorrow, im doing 2 valves to each side. any tips, first time doing a mazda!

H

hex0rz

+1y

Yea! visit this write-up:

It will definitely help alot I"m sure!

It will definitely help alot I"m sure!

toddluck

+1y

post pics as you go

3

3rdtimesacharm

+1y

this is my first time welding so its a little sloppy. i did a few practice runs first on scrap 1\4 steel and hit it with a 4 pound mallet and i didnt get any cracks in the welds so i felt safe with the welds!

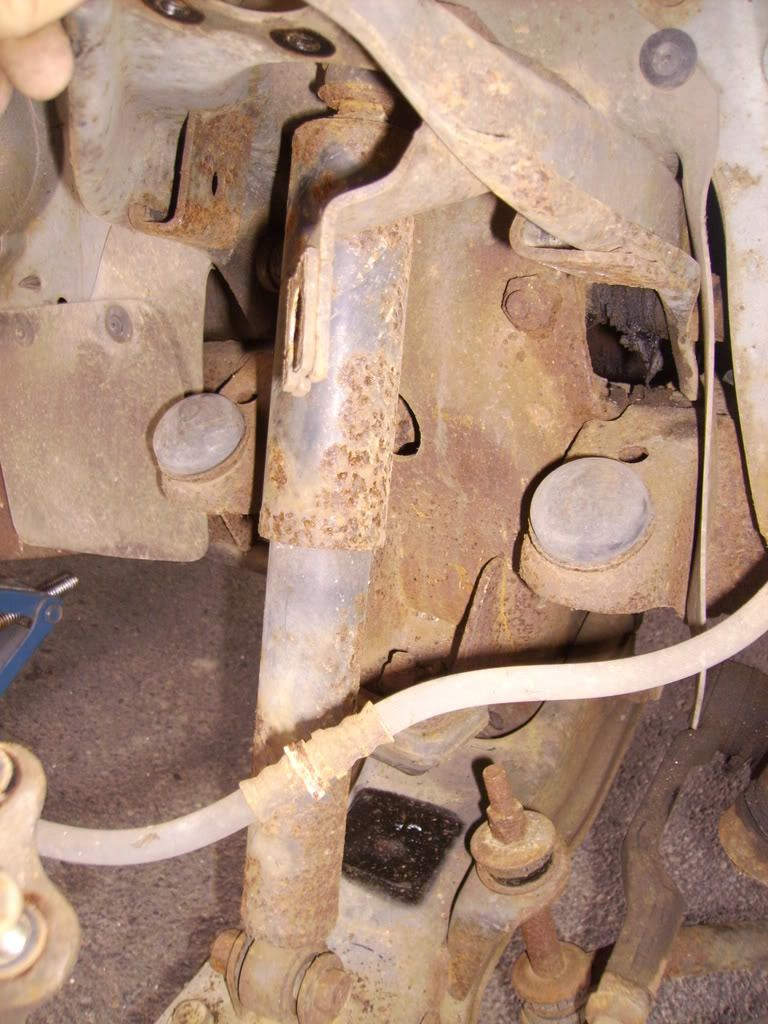

when i first started

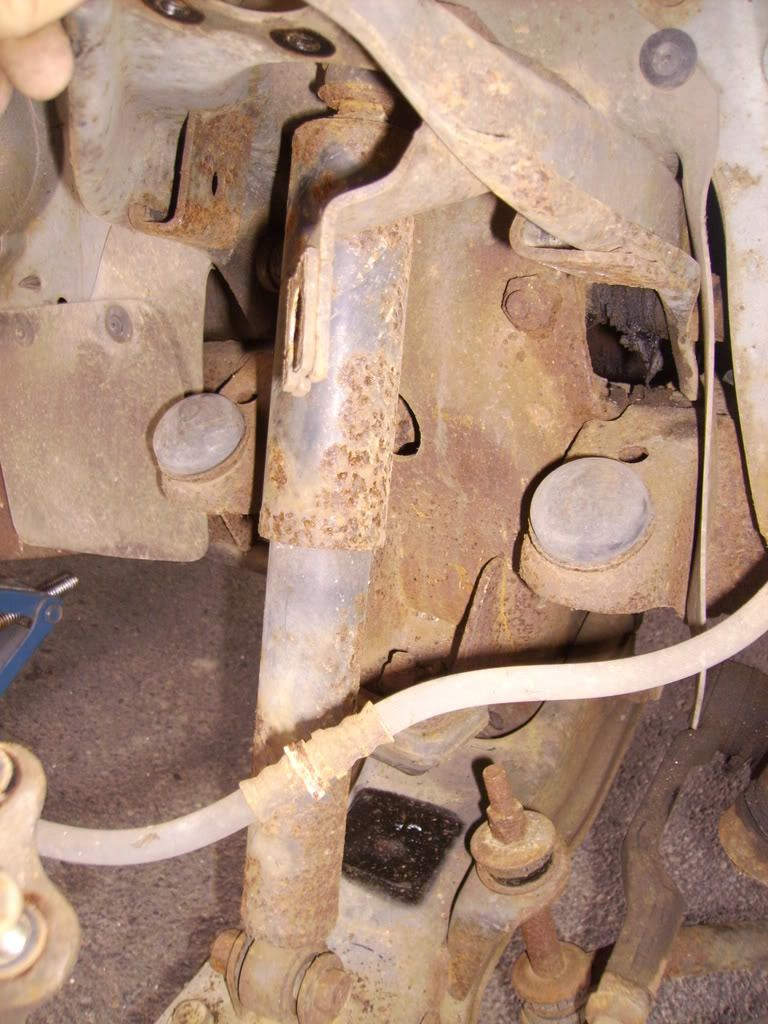

after every thing was cut

after i filled the lower control arm and welded the brackets

when i first started

after every thing was cut

after i filled the lower control arm and welded the brackets

3

3rdtimesacharm

+1y

3

3rdtimesacharm

+1y

the bag sits great when it is aired out but when i put a jack and lift it up it looks like when i air it up the bag will be alittle on a slant. is that normal?

H

hex0rz

+1y

Yes, as long as it is'nt rubbing on itself.

BTW, to ME, the welds look somewhat sketchy!

You said its your first time welding! First off, BAD! :\

Listen, maybe I should be saying this. But you definitely should have practiced on some steel the same thickness as this BEFORE undertaking such a BIG project!

I certainly don't want to hear about how your truck fell apart because of your welding!

This is something you drive on the road and that is around others. This is a VERY POTENTIALLY DANGEROUS situation!

Don't play around with safety!

Go back to your workbench, find steel the same thickness your welding and practice each weld. If you have a vice, put it in the vice and take that sledge hammer and beat at it the one way that would cause the most stress. Which is typically "pulling" it apart. If the steel breaks before the weld does and/or the steel is completely bent and the weld is'nt broke or cracked, your good to go.

But really, you need to put time and experience with welding before you do something that can kill you or others!

BTW, to ME, the welds look somewhat sketchy!

You said its your first time welding! First off, BAD! :\

Listen, maybe I should be saying this. But you definitely should have practiced on some steel the same thickness as this BEFORE undertaking such a BIG project!

I certainly don't want to hear about how your truck fell apart because of your welding!

This is something you drive on the road and that is around others. This is a VERY POTENTIALLY DANGEROUS situation!

Don't play around with safety!

Go back to your workbench, find steel the same thickness your welding and practice each weld. If you have a vice, put it in the vice and take that sledge hammer and beat at it the one way that would cause the most stress. Which is typically "pulling" it apart. If the steel breaks before the weld does and/or the steel is completely bent and the weld is'nt broke or cracked, your good to go.

But really, you need to put time and experience with welding before you do something that can kill you or others!

Related Discussions in Mazda Lowering Static

Thread

Posts

Last Post

12

L

last post by

Low5.0mazda +1y