S

09 F350

lockone

+1y

Looks good.

N

nlr

+1y

Here are some pictures from my truck of the NICE work Ekstensive did.

Nice and straight fender tubs in the rear. Yep got alot of awesome comments from alot of people on these!

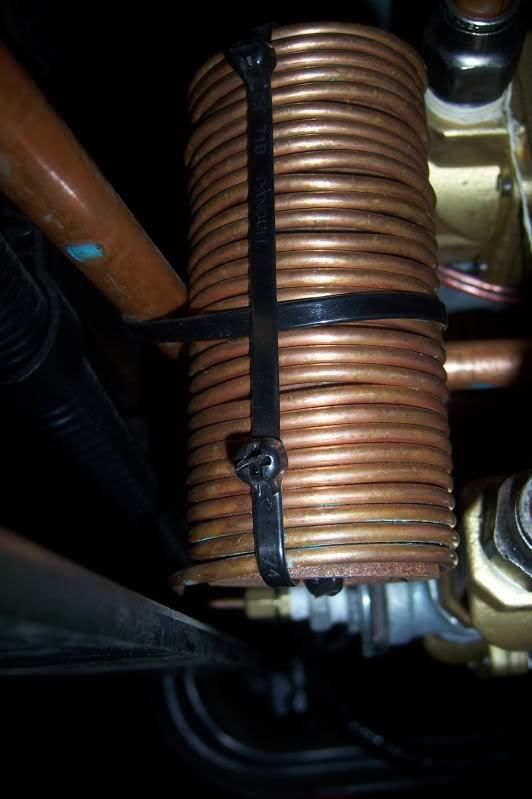

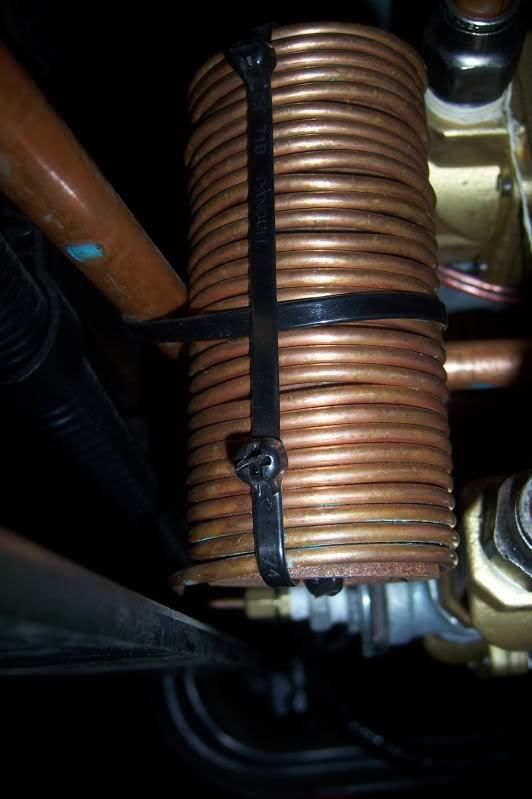

this is there anti sway device for the suspension bout 20 ft of coiled copper tube.

They put a very small tank maybe 5 gallons or so and used 2 small 400 scfm compressors. If you put the truck as low as it went and then tried to lift it up the front end would come up about half way and then stop as there was not enough air in the tank. You would have to sit there and wait in order for you to bring the rest of the truck back up.

This is the 5th wheel mounting structure they did as well as a notch. Truck still would not sit low enough in the rear. When told him it wasnt low enough they said that's all that could be done

here is a pic of the rear bag. When aired out it would rub against the diff case. You can see the bottom making contact just sitting there.

Here is a picture of the sway bar they installed. The truck wouldnt turn worth a shit...look in the picture and youll see the rub mark from the tire and wheel. Yep it hit and limited my steering dramatically.

truck would not sit level. Driver rear was an inch lower than the passenger rear

passenger rear

driver rear

a bunch of ball joints had to be changed because the zerk fittings they installed didnt have any ball spring checks in them to stop the stuff from coming back out after they pump em full of grease. This is after the trucks been there for 4 months.

upper bar mount bolts were so close to the frame that they were starting to grind into the main frame.

Here are the pictures from after Auto Extremes redid their work.

Added material and re notched the rear to provide the required distance to clear the axle and to provide clearance for the mounting gear for the upper bar to not hit the frame as it did when I got it.

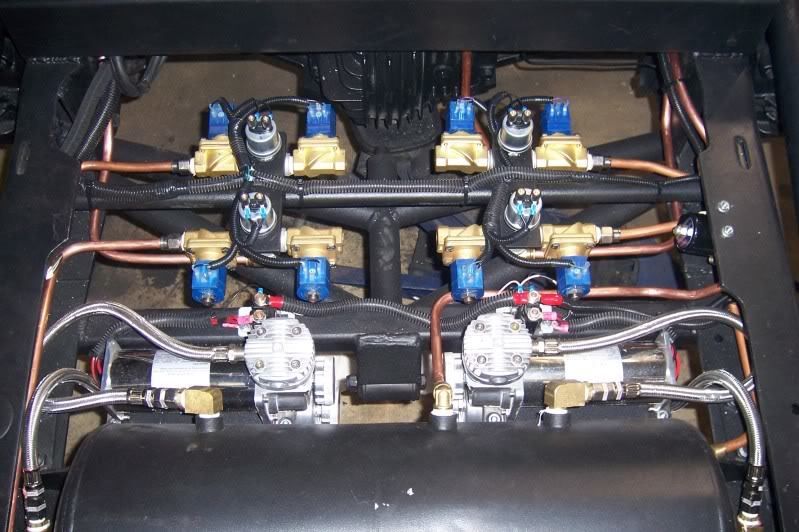

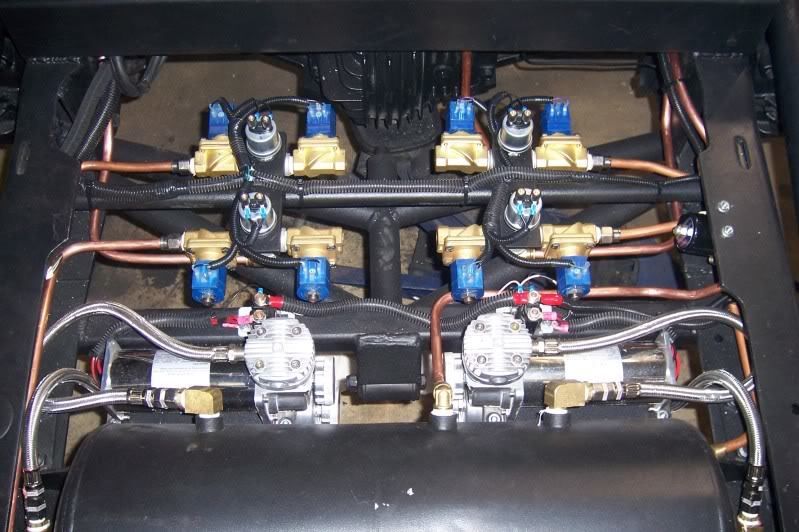

The only way to insure you can get the truck up and off the ground without having to wait forever is to use a larger tank and bigger air compressors. The shop installed 4 viar 460's i think as well as 4 more valves to give me independent control of the corners. When I got the truck from the first shop it would not sit level. Looked like the rear driver side was lot lower. From them I only had front and rear control. The new set up I can adjust each corner. very professional installation by the way!!

Ive got hundreds of pictures of their show quality work if anybody wants it. From brackets that had the solenoids mounted on them hanging from copper lines because the weld did not penetrate to the wire mess behind my dash .

I had to have the entire rear end of the the truck redone. I did not know then but I know who the good shops are now. Expensive lesson for sure.

Nice and straight fender tubs in the rear. Yep got alot of awesome comments from alot of people on these!

this is there anti sway device for the suspension bout 20 ft of coiled copper tube.

They put a very small tank maybe 5 gallons or so and used 2 small 400 scfm compressors. If you put the truck as low as it went and then tried to lift it up the front end would come up about half way and then stop as there was not enough air in the tank. You would have to sit there and wait in order for you to bring the rest of the truck back up.

This is the 5th wheel mounting structure they did as well as a notch. Truck still would not sit low enough in the rear. When told him it wasnt low enough they said that's all that could be done

here is a pic of the rear bag. When aired out it would rub against the diff case. You can see the bottom making contact just sitting there.

Here is a picture of the sway bar they installed. The truck wouldnt turn worth a shit...look in the picture and youll see the rub mark from the tire and wheel. Yep it hit and limited my steering dramatically.

truck would not sit level. Driver rear was an inch lower than the passenger rear

passenger rear

driver rear

a bunch of ball joints had to be changed because the zerk fittings they installed didnt have any ball spring checks in them to stop the stuff from coming back out after they pump em full of grease. This is after the trucks been there for 4 months.

upper bar mount bolts were so close to the frame that they were starting to grind into the main frame.

Here are the pictures from after Auto Extremes redid their work.

Added material and re notched the rear to provide the required distance to clear the axle and to provide clearance for the mounting gear for the upper bar to not hit the frame as it did when I got it.

The only way to insure you can get the truck up and off the ground without having to wait forever is to use a larger tank and bigger air compressors. The shop installed 4 viar 460's i think as well as 4 more valves to give me independent control of the corners. When I got the truck from the first shop it would not sit level. Looked like the rear driver side was lot lower. From them I only had front and rear control. The new set up I can adjust each corner. very professional installation by the way!!

Ive got hundreds of pictures of their show quality work if anybody wants it. From brackets that had the solenoids mounted on them hanging from copper lines because the weld did not penetrate to the wire mess behind my dash .

I had to have the entire rear end of the the truck redone. I did not know then but I know who the good shops are now. Expensive lesson for sure.

balcar

+1y

lol crimps, you would think it would be soldered at least with what they charge, ow well. I've had to fix a few things from there, ow well, hope they up the quality sometime soon.

okcderek

+1y

Wow, isnt there moto bagging the best and fixin the rest..?? I thought I read that on one of their shirts..

N

nlr

+1y

yep thats their moto. ...I paid close to 20 grand and have another 9k fixing all their work making it the way it should have been when I picked it up. They will never get another dime out of me and I will tell everyone about my experience.

Ill be at showfest with the truck and I will be handing out about 3000 cds with the way the truck was from Ekstensive and the work they performed(very detailed pictures). There will also be pictures of all the repair work that was done to make it right(with more pictures). There is probably about 100 -150 pictures on the cd and all the images are labeled who did the work.

Here is what was wrong with the truck.

Problems with truck:

Tires provided were not what I ordered. I specifically ordered a tire that can be run in any direction make rotations easy. The tire they provided cannot.

power steering line was extended with brass fittings and leaked at this point

fitting in rack and pinion was incorrect and leaks

Sway bar was to long and tire would hit the sway bar limiting turning radius

skeleton frame of front quarter panel/fender above tires was cut and not clearanced enough and would rub tires( put a groove in them)

Power wire for compressors was inadequate size and a 100 amp fuse installed. If short occurred wire would melt and cause a fire before fuse would blow.

Zerk fittings installed did not have ball spring and all grease was pushed out

bad ball joints on 3 positions on control arms

air valve mounting bracket was hanging as the weld was not good enough to support the weight. Copper lines and wires were supporting it.

Digital display on dash was damaged due to short in wires when installing gauge and switches. ( damage cause performed by ford, computer recorded short and when it happened). The short damaged the remote entry key pad on door which is tied together with the digital dash.

Pinion angle was incorrect on drive line

Rear axles were shortened to much

rear bars incorrect thus pinion angle was incorrect

brake line for the rear brakes was completely crushed

rear bags already had rub marks

bed was not bolted down

bed was not clearanced for bars and as truck would go down the bar ends would bottom out on bed bending the bed upwards.

rear tubs were completely crooked and were to shallow as tires would rub on the inside of them.

Rear fenders were not clearanced enough and sliced into the tires.

Truck would not sit level and . Driver rear would sit lower than passenger rear. Passenger front would sit higher than driver front.

too small air tank

not enough valves to allow for leveling of truck

rear was not lowered like promised

compressors were to small

hopefully others learn from this and dont fall into the hype of they are the best because they do alot of sema trucks and get in magazines. Well my stuff wasnt a sema truck nor was it going into a magazine so I guess this is what the normal guy gets.

Ill be at showfest with the truck and I will be handing out about 3000 cds with the way the truck was from Ekstensive and the work they performed(very detailed pictures). There will also be pictures of all the repair work that was done to make it right(with more pictures). There is probably about 100 -150 pictures on the cd and all the images are labeled who did the work.

Here is what was wrong with the truck.

Problems with truck:

Tires provided were not what I ordered. I specifically ordered a tire that can be run in any direction make rotations easy. The tire they provided cannot.

power steering line was extended with brass fittings and leaked at this point

fitting in rack and pinion was incorrect and leaks

Sway bar was to long and tire would hit the sway bar limiting turning radius

skeleton frame of front quarter panel/fender above tires was cut and not clearanced enough and would rub tires( put a groove in them)

Power wire for compressors was inadequate size and a 100 amp fuse installed. If short occurred wire would melt and cause a fire before fuse would blow.

Zerk fittings installed did not have ball spring and all grease was pushed out

bad ball joints on 3 positions on control arms

air valve mounting bracket was hanging as the weld was not good enough to support the weight. Copper lines and wires were supporting it.

Digital display on dash was damaged due to short in wires when installing gauge and switches. ( damage cause performed by ford, computer recorded short and when it happened). The short damaged the remote entry key pad on door which is tied together with the digital dash.

Pinion angle was incorrect on drive line

Rear axles were shortened to much

rear bars incorrect thus pinion angle was incorrect

brake line for the rear brakes was completely crushed

rear bags already had rub marks

bed was not bolted down

bed was not clearanced for bars and as truck would go down the bar ends would bottom out on bed bending the bed upwards.

rear tubs were completely crooked and were to shallow as tires would rub on the inside of them.

Rear fenders were not clearanced enough and sliced into the tires.

Truck would not sit level and . Driver rear would sit lower than passenger rear. Passenger front would sit higher than driver front.

too small air tank

not enough valves to allow for leveling of truck

rear was not lowered like promised

compressors were to small

hopefully others learn from this and dont fall into the hype of they are the best because they do alot of sema trucks and get in magazines. Well my stuff wasnt a sema truck nor was it going into a magazine so I guess this is what the normal guy gets.

L

low95xlt

+1y

wow sorry to hear sounds like the headaches i went thru

balcar

+1y

normal guy i dont think has 20k to spend, and if you have 20k to spend you should have no issues. I have a hard time charging 3500-4k for bag jobs (granted that is just a basic setup, fbss) but even for that price I make sure there are no problems. A friend of mine that had a eclipse done there had huge amounts of problems, and it spent about 6 months there once for "repair" work. I wish everyone the best, so hopefully they start to get better soon.

WL

wide load c-30

+1y

That was a horrible hack job. Any word on a partial refund?

balcar

+1y

Now thats funny

lockone

+1y

Auto Extremes does some amazing work.

Related Discussions in General Discussion

Thread

Posts

Last Post

7

last post by

Babyfartzmageezaks530 +1y

5

A

last post by

Alreadyhavingissues +1y