turbo V8, ultimate b2200 conversion, "Stranger". Final pics

94746 views

399 replies

51 following

turbo V8, ultimate b2200 conversion, "Stranger". Final pics

baha

+1y

I was always curious about learning how to plastic weld. Do you have any pics of what you are using?

S

sickkid

+1y

i like the way the truck seems to be coming along. I do have one question/statement about the plastic welding of the front bumper cover. Im not sure on your experience with plastic welding but you could have eliminated the need for bracing the plastic by doing a v-groove to both parts of the splice followed by a double sided plastic stitch weld with wire mesh welded to the inside.

Basically you bring the parts together, grind out a groove on both sides of the seem, take a drill with a small drill bit and drill holes about half an inch or so apart. Then you tack, then speed weld both sides with mesh going to the backside before welding, then fill with a 2part epoxy plastic filler, sand, sanding filler, sand.

Might take a bit longer but would eliminate the need for bracing the plastic and eliminating the bolts holding it together. And its probably still not to late since you could just weld the bolt holes up.

When plastic welding, the weld should act and have the same strenghth as the original part. If done right you can break every mounting location tab off of a car bumper, weld them back on the bumper and they should hold as if they were original.

If you have any questions or ideas let me know, ill help if i can.

Basically you bring the parts together, grind out a groove on both sides of the seem, take a drill with a small drill bit and drill holes about half an inch or so apart. Then you tack, then speed weld both sides with mesh going to the backside before welding, then fill with a 2part epoxy plastic filler, sand, sanding filler, sand.

Might take a bit longer but would eliminate the need for bracing the plastic and eliminating the bolts holding it together. And its probably still not to late since you could just weld the bolt holes up.

When plastic welding, the weld should act and have the same strenghth as the original part. If done right you can break every mounting location tab off of a car bumper, weld them back on the bumper and they should hold as if they were original.

If you have any questions or ideas let me know, ill help if i can.

mtrain

+1y

Actually, I did that as well. I just used the steel for extra insurance.

I now have many chemicals left over for an accident to any of my other cars.

Here is the link where I learned how to do this.

mtrain

+1y

Can you tell me more about your experience with them, and what the problem was that you were having?

mtrain

+1y

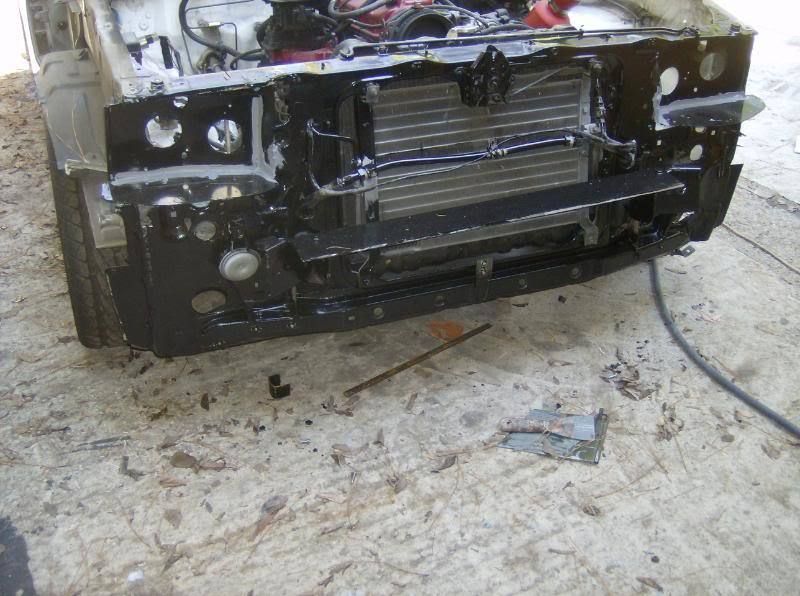

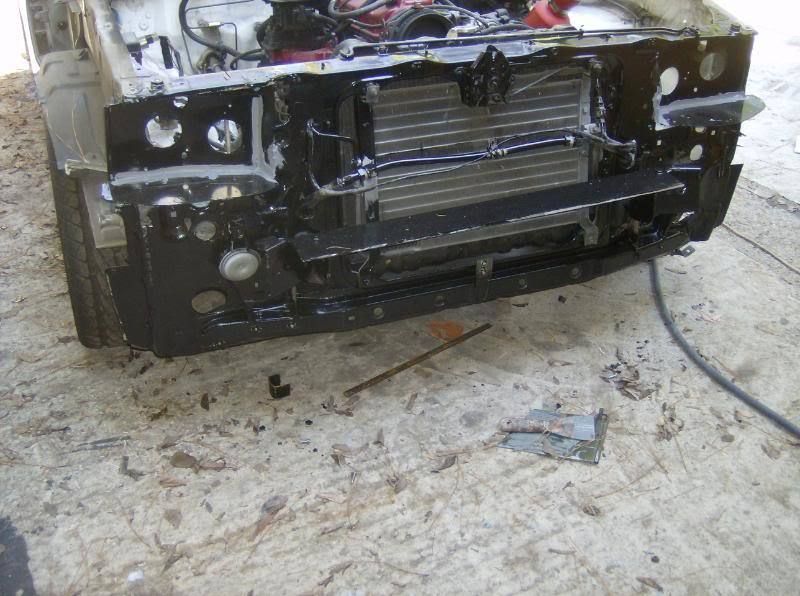

Here is the modded front end for the Ranger headlights.........

mtrain

+1y

One of the main things was to get the Ranger headlights to set right in the truck.

mtrain

+1y

Also, I almost forgot, the brake issue is fixed.

I was trying again to bleed the system with no luck. Then I had a tool roll under the truck. There appeared to be a small pool of liquid.

You guessed it, brake fluid. The ONLY hard, factory brake line that I didn't replace just decided to blow. And, blow it did. Now I have to repaint a few things under the hood..........damned it.

Fixed the line with a new one. Oh, and I also bought a new master cyl while I was at it.

I bled the new master on the truck, then went through all of the lines. It had brakes but almost at the end of pedal travel.

I looked under the dash, well when I changed pedal setups from auto to manual tranny I didn't put the pin back in that locates the master cylinder rod.

I reconnected the pin, and also adjusted the rod out just a few turns while I was under there, and now the brakes are firm just as they should be.

I was trying again to bleed the system with no luck. Then I had a tool roll under the truck. There appeared to be a small pool of liquid.

You guessed it, brake fluid. The ONLY hard, factory brake line that I didn't replace just decided to blow. And, blow it did. Now I have to repaint a few things under the hood..........damned it.

Fixed the line with a new one. Oh, and I also bought a new master cyl while I was at it.

I bled the new master on the truck, then went through all of the lines. It had brakes but almost at the end of pedal travel.

I looked under the dash, well when I changed pedal setups from auto to manual tranny I didn't put the pin back in that locates the master cylinder rod.

I reconnected the pin, and also adjusted the rod out just a few turns while I was under there, and now the brakes are firm just as they should be.

mtrain

+1y

Alright here you go.

I bought a set of upper, and lower control arms from a member here that bought them from Dallas Hotrod Parts.

Here is the first mock up.

It was difficult since I didn't have the directions, but after a few calls to DHR I got everything figured out. One thing I can tell you is that you WILL have to weld the lower arm mounting rail to the frame, and its a bitch to get the old bushings out, and I had a torch.

I asked the owner {I guess he is a one man show, but I don't know} of DHR if those arms would work with Ridetec Shockwave air shocks, he said, "YES", but they don't.

Here is the problem. Look at the stock DHR upper arm.

Do you see where I cut it? Well that was because it hits the rubber bellow's, hard, at that angle.

Here is one I modded to get enough clearance.

Even with that much bow its still close, with the smallest bellows SW's that Ridetec sells. It was a good thing I had some DOM steel laying around, a good torch and sound vice to make that bend.

Here is another mock up with the upper arm with the new tube, and Shockwave shock. Please note that this was just a mock up as you can see that the turbo intake tube silicon isn't clamped yet.

Also, I had to buy a drop spindle for these arms as well.

I bought a set of upper, and lower control arms from a member here that bought them from Dallas Hotrod Parts.

Here is the first mock up.

It was difficult since I didn't have the directions, but after a few calls to DHR I got everything figured out. One thing I can tell you is that you WILL have to weld the lower arm mounting rail to the frame, and its a bitch to get the old bushings out, and I had a torch.

I asked the owner {I guess he is a one man show, but I don't know} of DHR if those arms would work with Ridetec Shockwave air shocks, he said, "YES", but they don't.

Here is the problem. Look at the stock DHR upper arm.

Do you see where I cut it? Well that was because it hits the rubber bellow's, hard, at that angle.

Here is one I modded to get enough clearance.

Even with that much bow its still close, with the smallest bellows SW's that Ridetec sells. It was a good thing I had some DOM steel laying around, a good torch and sound vice to make that bend.

Here is another mock up with the upper arm with the new tube, and Shockwave shock. Please note that this was just a mock up as you can see that the turbo intake tube silicon isn't clamped yet.

Also, I had to buy a drop spindle for these arms as well.

mtrain

+1y

Not that anyone is actually reading this anymore, but today I burned the $hit out of my fingers. I don't know if I will ever learn that after grinding aluminum it gets very HOT!........lol.

Here is what happens when your welding up V-bands on one side of your exhaust pipes, then switch to the other side, and don't think about the one you just welded there before.

Here is what happens when your welding up V-bands on one side of your exhaust pipes, then switch to the other side, and don't think about the one you just welded there before.

mtrain

+1y

Ok, you guys want some meat, how about this...................First B with 14" front disc brakes.

Old vs new in this pic.....

On the truck.

Homemade 1/4 adapter

Old vs new in this pic.....

On the truck.

Homemade 1/4 adapter

Related Discussions in Mazda Projects

Thread

Posts

Last Post

852

last post by

skrapinsask +1y

150

last post by

cherokeed +1y