84 CHEVY CREW CAB DUALLY PROJECT

evilbill

+1y

they are new 454 mounts if they flex too much ill chain that bitch down to the frame on the drivers side ...old school style ...lol

I

iarodder

+1y

they are new 454 mounts if they flex too much ill chain that bitch down to the frame on the drivers side ...old school style ...lol[/quote]

Just so you know they do make interlocking motor mounts so they can only flex so far, Energy Suspension makes them. I bought a pair a few years ago for my pro street 53 with a 468 big block, they were great never broke them.

Just so you know they do make interlocking motor mounts so they can only flex so far, Energy Suspension makes them. I bought a pair a few years ago for my pro street 53 with a 468 big block, they were great never broke them.

W

watahyahknow

+1y

i allso seen a hack for the old style mounds where they drill a hole all the way through the plate rubber and plate then drill out the plate at the motor side bigger so the bolt can move a little and tap a tread in the hole on the other side , they used a good grade steel bolt all the way through and grinded down the head a little to get the whole thing fit on the motormount again , that way should the rubber tear it still holds the damper together , snugging the bolds a little thighter prolly stiffens it up some too

comegetsome

+1y

My trans is like that too....real close to trans tunnel....and my motor flexes alot but only when your cranking it or switching it off

04_duramax

+1y

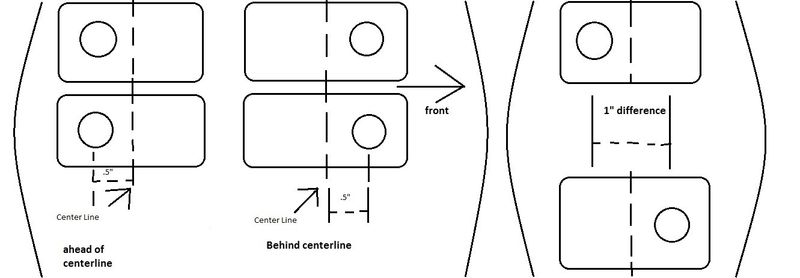

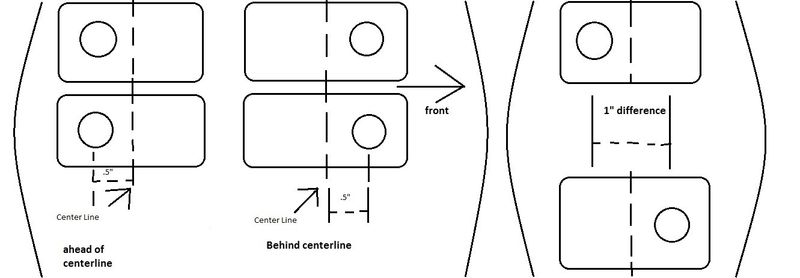

mine is really tight also bud! I used the dodge mounts, and i made the bolt holes (on the engine half) offset .5" of center of the mount. that way, you can swap the mounts from one side to the other of the engine. one way sets the engine .5" behind centerline of the mounts, the other way sets .5" ahead of center line of the mounts.

when i fitted the engine up the first time, it sat really really close. so i swapped sides with my mounts, it moved it 1" forward from where it was.

when i fitted the engine up the first time, it sat really really close. so i swapped sides with my mounts, it moved it 1" forward from where it was.

04_duramax

+1y

your truck looks awesome man! i like it! im jealous that mine isnt body dropped & Z'd! mine is gettin tag & insurance today!

04_duramax

+1y

heres mine! i shortened them 3/4". look how the bolt hole on the shiny one is ahead of centerline.

04_duramax

+1y

lol this will make me not sound like a crazy person lol.

it might make sense lol.

it might make sense lol.

evilbill

+1y

thanks thats a good idea i will look into it, i just figured factory mounts were nice and cushy and might keep vibrations down lol

evilbill

+1y

good to know im not the only one haha..

Related Discussions in Dually Projects

Thread

Posts

Last Post

546

A

last post by

Airnewb91 +1y

193

last post by

Airnewb91 +1y