75 Dually Project - 22s and stylin

75dually

+1y

I have decided to change course on the front end assembly. I am going with the stock dually brake assembly along with my 3" drop spindles. So I mocked up the assembly this evening and I am pleased with results.

I will still pie cut the upper a-arm to relieve the extreme angle on the upper ball joint. On the a-arm I cut up I will replace it with one off the donor burb.

I am still thinking about moving the cross member forward 1". Probably more trouble than it is worth, but it beats having to cut up the firewall and tubing it.

So today I took the lower a-arms over to a friends shop and pressed in new lower ball joints, and this weekend I will put the new upper ball joints in. I also have the new inner and outer tie rods to put on as well. So lots of little jobs to get accomplished.

I will still pie cut the upper a-arm to relieve the extreme angle on the upper ball joint. On the a-arm I cut up I will replace it with one off the donor burb.

I am still thinking about moving the cross member forward 1". Probably more trouble than it is worth, but it beats having to cut up the firewall and tubing it.

So today I took the lower a-arms over to a friends shop and pressed in new lower ball joints, and this weekend I will put the new upper ball joints in. I also have the new inner and outer tie rods to put on as well. So lots of little jobs to get accomplished.

luifer76

+1y

Nice!..... are you gonna be cupping the lowers?

75dually

+1y

Not sure yet... I am going to set up the air bags later this weekend and see what I want to do.

If I end up cupping them I have a buddy who owns a company that installs those farming center pivots sprinkler systems, and he has some perfect 10" well casing scrap laying around. So at least if I do cup the lowers I have the right stuff to do it with.

luifer76

+1y

cool.....

75dually

+1y

OK I went and spent some serious money today. I purchased the Accuair e-level setup along with their new iLevel system. They are just about to release the Android version of the iLevel. They said it should be a couple of weeks before they release it, so that was cool.

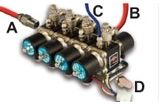

However I did not buy their valve assembly. Their valve assembly is a 3/8", and the more I talked to them about it and asked them directly how fast is really was, the more it turned out it was slower than the current 3/8" valve assembly I have today on another ride. Basically the sales guy admitted that their systems speed is between a 1/4" and 3/8" normal valve assembly. Not on my dually! So I went with the Airbaggit 1/2" airengine valve system. And before you ask, yes you can run another companies valve system off their controller. Maybe not as plug and play as I would have wanted, but I am not going to put up with that slow of a system speed for that much money.

I also got my rims sent off to Trevor (Thanks Trevor for all the help today!) at Tennessee Wheel and Tire. I can't wait until these are back and I get the tires mounted up.

So now I'm broke... But HAPPY! HAPPY, HAPPY, HAPPY!!!

However I did not buy their valve assembly. Their valve assembly is a 3/8", and the more I talked to them about it and asked them directly how fast is really was, the more it turned out it was slower than the current 3/8" valve assembly I have today on another ride. Basically the sales guy admitted that their systems speed is between a 1/4" and 3/8" normal valve assembly. Not on my dually! So I went with the Airbaggit 1/2" airengine valve system. And before you ask, yes you can run another companies valve system off their controller. Maybe not as plug and play as I would have wanted, but I am not going to put up with that slow of a system speed for that much money.

I also got my rims sent off to Trevor (Thanks Trevor for all the help today!) at Tennessee Wheel and Tire. I can't wait until these are back and I get the tires mounted up.

So now I'm broke... But HAPPY! HAPPY, HAPPY, HAPPY!!!

M

mdub4life29

+1y

whats ur plan for wheels? any custom milling?

75dually

+1y

I have a set of Accurides. Below is a picture of them the day I picked them up. I talked to Trevor at TN Wheel and he said that the Accurides are actually thicker than the Alcoa's. So they are a better candidates for machining.

I am not having any special machining done to them at this time. I am however going to have the rear 4 rims milled on the face to reduce the overall width. Maybe at some point in the future I will have something cool done to them, but the budget just wont take it right now.

luifer76

+1y

Nice! thats what i always tell the wife after buying parts for my truck im broke but happy lol...

75dually

+1y

I try not to tell the wife what I am spending on my projects... That way I don't have to sleep with one eye open! Safer that way!

luifer76

+1y

lol....

Related Discussions in Dually Projects

Thread

Posts

Last Post

546

A

last post by

Airnewb91 +1y

193

last post by

Airnewb91 +1y