Street Source is shutting down April 30th, 2026. Read the announcement

R

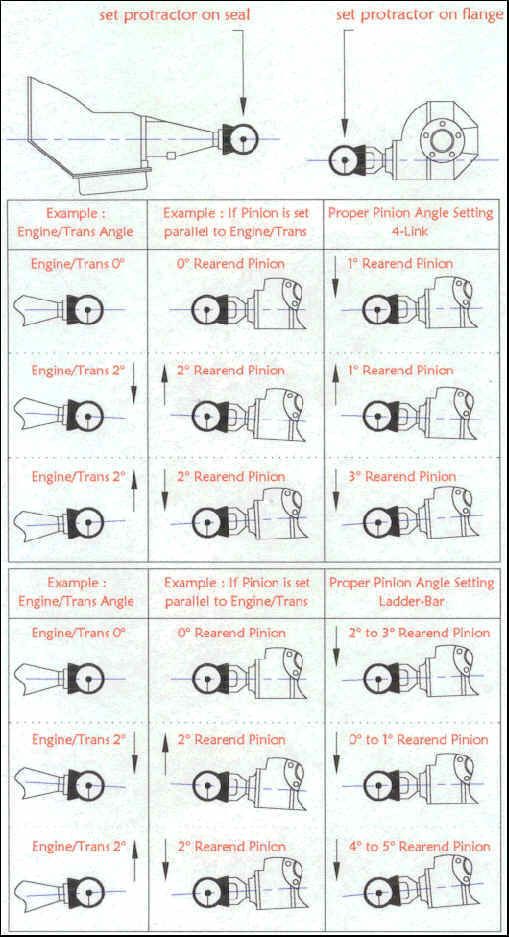

pinion angle 2 piece driveshaft

pro53

+1y

Could I give the trans and the carrier bearing a postive number and It work?

john-e bravada

+1y

Yeah but you'd have to worry about fan, trans tunnel, and carrier bearing clearance. You'll need to lengthen your upper or shorten your lower links.

pro53

+1y

Yea dropped the lower links last night, jacked it up to correct angle, will have to notch a brace in frame for driveshaft to clear, then shorten the lower links and stretch the top ones to keep rearend where it is. Cut the track bar loose reweld and might have to redo the bottom bag brackets. Thats why I hate buying other peoples stuff.

So agreed, need to point the rearend up to a postive 5 deg?

john-e bravada

+1y

Agreed, that's a bummer!

krewzlo

+1y

I know its a lot of work but do the axle, changing the engine and tranny mounts, exhaust, and all the clearance with that will be more in the long run. Theres an old saying, do it right or do it again.

pro53

+1y

When I went to take the driveshaft out to take to Northwest drivetrain to get checked out, I noticed one of the on the front yoke of the transmission was worn out for some reason. The tabs that center the u joint, one was worn out caused the unversal to slide in the cradel (.100) almost an 1/8 of an inch. Between this moving around up front the carrier bearing rubber being cracked and sloppy joints, and also the other rear joint that somebody bolted in but did not have it all the way pushed into the yoke, had it sitting on top of the tab bolted down, alowed the rear u joint to slide around. Having the driveshaft all redone with new front yoke, carrier bearing and all new joints, just going to put it back in and take it for a drive. Should ride way better. Will just address the issue on the pinion angles being off later. Sure dont want to redo it all right now, to busy with other stuff.

Related Discussions in Dually Suspension

Thread

Posts

Last Post

Michigan Metal Works A-Arm group buy 88-98 Chevy/GMC 1500 to 3500 and dually's

S

last post by

Strokersace +1y

8

8

S

last post by

Strokersace +1y