Sheetmetal shaping

guiltybydesign

+1y

Lets see some advanced shaping and forming.

guiltybydesign

+1y

Lets see some advanced shaping and forming. Heres a set of teardrop wheel tubs im building for the F100. I make mine from 2 pieces and form the edges with my tank die in the bead roller.I make a template of the desired shape out of a piece of 3/4'' wide strap by stretching the outer edge (pic 3). I shrink the edge to be rolled, even more where the radius is tighter. After the edge is shrunk I run both edges through the roller to get the radius, then with a little more shrinking I have the 2 halves fitting together. Some welding, grinding, and filing and they are done. A little more time involved but looks way better than a welded square edge imo.

T

toreadorxlt

+1y

built a pullmax style machine.. then started on these 1/4's 2 nights ago.

leydbck

+1y

Wow. Both of those look good.

guiltybydesign

+1y

That's awesome. I had the chance to buy a pullmax a few years back but wasn't into shaping as much as I am now, regret it now. I actually just machined a 33-34 beltline bead a few weeks ago just to have.

Not much shaping in this one but I was very happy with how it turned out.

Not much shaping in this one but I was very happy with how it turned out.

T

toreadorxlt

+1y

Awesome work. Did this one recently. Started with a shell...split it, fixed a dent, and extended it... Pics are out of order but you get the point

T

toreadorxlt

+1y

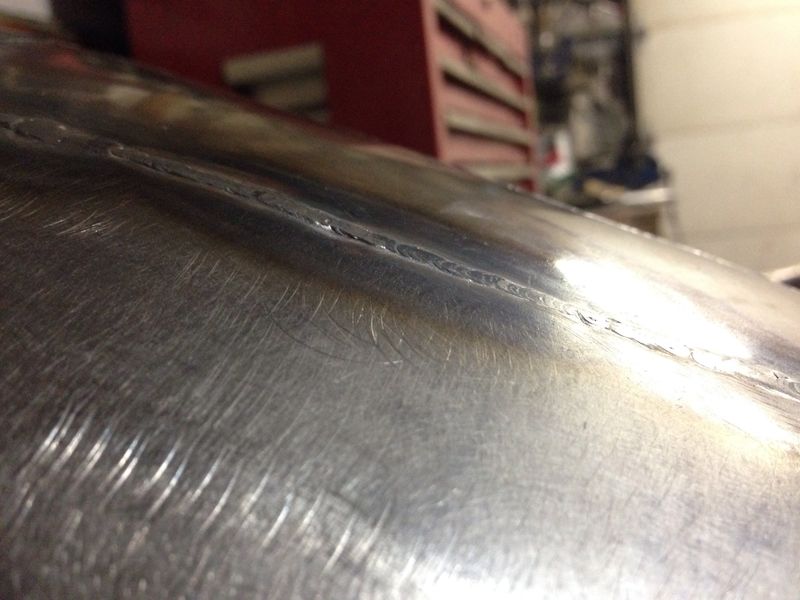

Day 3 on this. It'll look better soon

guiltybydesign

+1y

Redid the bumper ends on a buddys 55 caddy. Got about 13 hrs into them and after a little more filing theyll be ready for chroming.

jaredmxg

+1y

Nice work. I know there is a lot that actually gos into forming metal, that's for sure. Its not quite as easy as it looks. Good job on everything.

jaredmxg

+1y

You may have said it, but what gauge is that metal? I have found it more difficult to work with 18 and up, VS the thicker metals, 16 and below.

Related Discussions in Mini Truckin General

Thread

Posts

Last Post