***Custom Frame***

jaredmxg

+1y

I have had nothing but problems when welding to cast weather it is hight heat or whatever, with my mig. You can arc weld it with a rod spacificly for cast from what i have herd from multiple people. I just know from my experiance i have had my link tabs break of while riding down the road, I had it rewelded back on with alot alot of heat and it held untill i redid my rear frame.

onehot69stepside

+1y

Originally posted by VinceBHC

I've always just weld really hot to casting. Never had a problem.

same here. have done quite a few like that and haven't broken one yet.i think alot of people might be under the impression that its cast iron, when its really cast steel.

I've always just weld really hot to casting. Never had a problem.

same here. have done quite a few like that and haven't broken one yet.i think alot of people might be under the impression that its cast iron, when its really cast steel.

badcoma

+1y

not as done as most of the ones shown but i have some picture of mine in my profile

tofnlows10

+1y

Originally posted by badcoma

not as done as most of the ones shown but i have some picture of mine in my profile

not as done as most of the ones shown but i have some picture of mine in my profile

T

thrownsparx

+1y

all of those are pretty impressive......

travis98s10

+1y

Edited: 9/7/2006 6:07:45 AM by travis98s10

Heres mine... Is nothing compared to alot of these badass frames but this one was just to prepare me for the one i really want to build in a few years. :D Stock S10 front clip btw, just smoothed out

Heres mine... Is nothing compared to alot of these badass frames but this one was just to prepare me for the one i really want to build in a few years. :D Stock S10 front clip btw, just smoothed out

tofnlows10

+1y

looks good

jeebus @ mmw

+1y

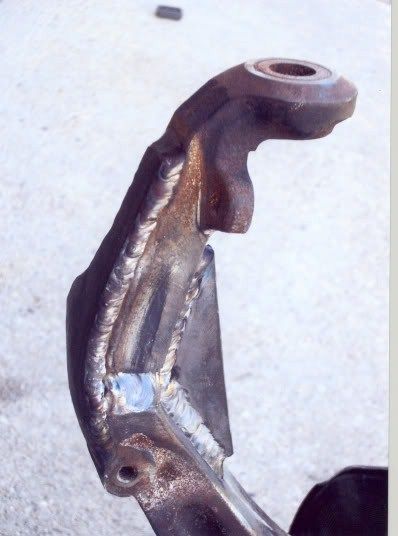

heres mine in progress. nothin special. once agian, stock front clip, smoothed out and going to be sectioned alittle bit. 2x3 from the motor back.

Heres shots of the old backhalf...since im buildin a new frame, im still using this rear half section....just changing all the link mounts, and got a new axle....pumps and fuel cell mounts are the same still, some trick new battery mounts are gonna be installed also....

Heres shots of the old backhalf...since im buildin a new frame, im still using this rear half section....just changing all the link mounts, and got a new axle....pumps and fuel cell mounts are the same still, some trick new battery mounts are gonna be installed also....

jcordova

+1y

Originally posted by lownism0

I was told to weld to cast you need to heat it red hot then weld it with a nickel rod then let it cool very slowly.

Yep, that's what they did with my spindles. Got them red hot, nickle rod, then buried in sand to cool.....

Not trying to hijack thread though......

I was told to weld to cast you need to heat it red hot then weld it with a nickel rod then let it cool very slowly.

Yep, that's what they did with my spindles. Got them red hot, nickle rod, then buried in sand to cool.....

Not trying to hijack thread though......

D

dreadeddragger

+1y

here are some frames being built at Draggers Inc see more at www.myspace.com/draggershotrods

http://i113.photobucket.com/albums/n214/draggershotrods/PICT0334.jpg

http://i113.photobucket.com/albums/n214/draggershotrods/PICT0005-2.jpg

http://i113.photobucket.com/albums/n214/draggershotrods/PICT0334.jpg

http://i113.photobucket.com/albums/n214/draggershotrods/PICT0005-2.jpg

Related Discussions in Air Ride Suspensions

Thread

Posts

Last Post