Project: ALMOST LEGAL

dirtracer14

+1y

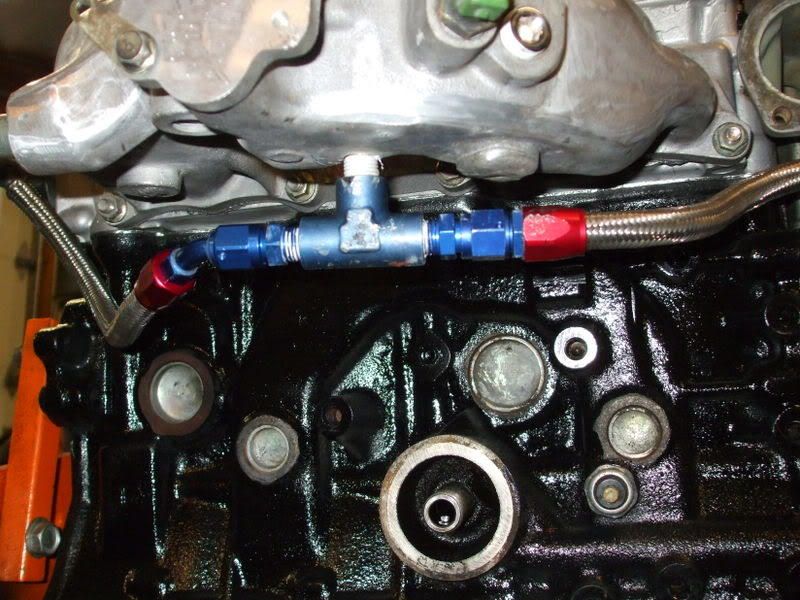

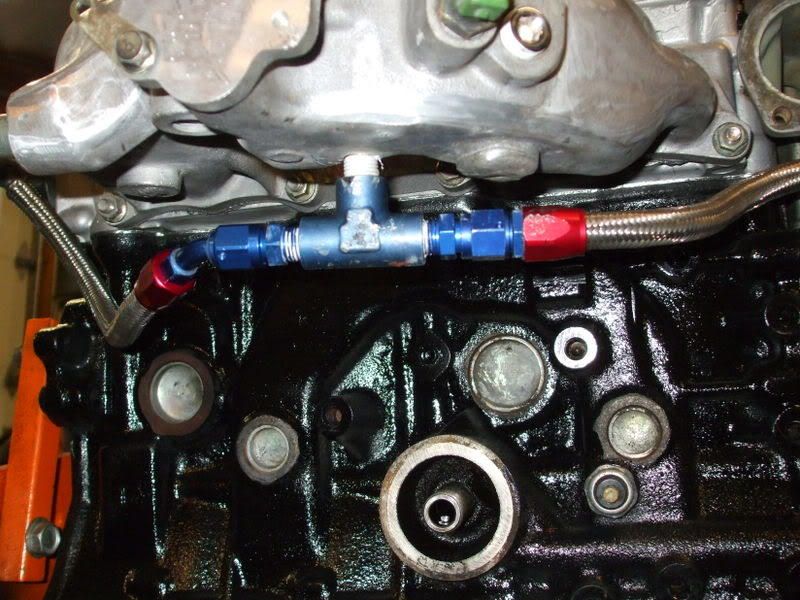

Had to do away with the ugly lines underneath the intake. Think this looks a little better

dropped90(justin)

+1y

how exactly did you shave the intake up? did you just tig weld the holes up and then smooth it back down?

-justin

-justin

dirtracer14

+1y

I used a grinder and flap wheel i ground all the bosses off from the vacum lines then welded and reground. I was not looking to polish the whole intake just clean up all the bs on it.

dropped90(justin)

+1y

so did you use a tig welder or what? did you just use some aluminum to stick in the egr port?

-justin

-justin

dirtracer14

+1y

Well i took it to guy down the road from me he used a mig with spool gun. He tested a few spots then ground it down to make sure it would weld good. We made plugs for the egr ports then left them a little low and welded so we could grind them back flush. If it wasnt snowing all day i would have dropped the motor in!

dirtracer14

+1y

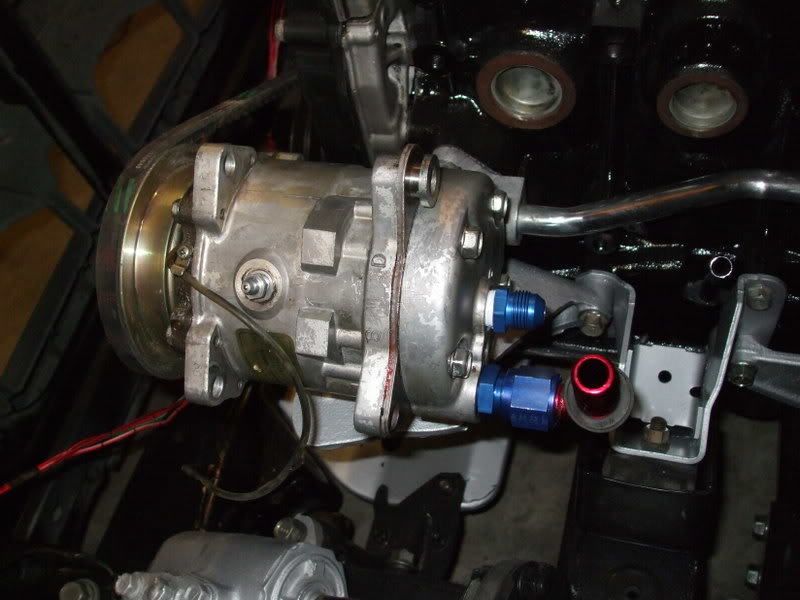

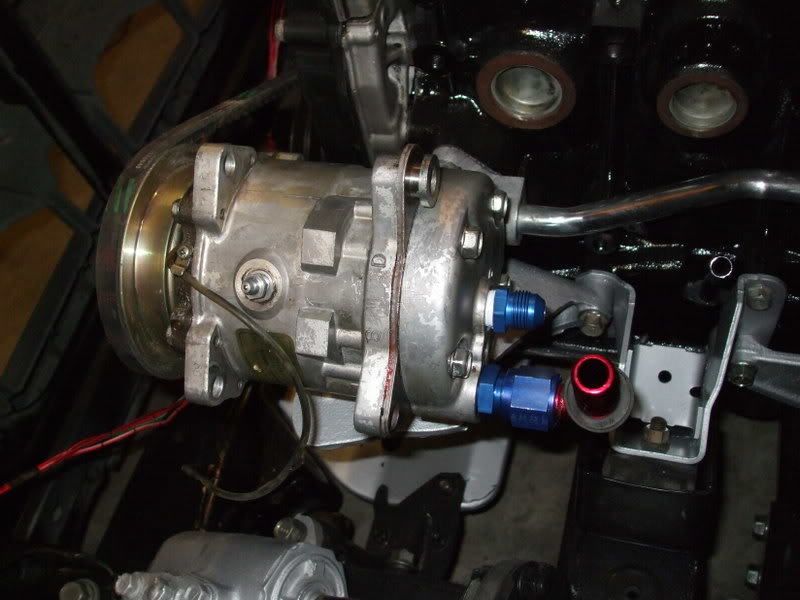

Got a few things done today finished the edc on the motor still need to get air filter and lines. Set the motor in so we can plumb and wire it. I hope about 2 to 3 weeks it will be a driver.

immortal1 (linn)

+1y

Looking great! That EDC looks right at home Will have to work on the zerk fitting mod for the daughters truck once I get mine a little farther along.

dirtracer14

+1y

Not sure the zerk is going to be the hot deal. The case is sealed and when pumping the grease in might be a bit much. There is no vent and i dont want to put to much pressure in there. I think we will just pull the zerk and pump it in that way. I hope to find out in the next few weeks.

immortal1 (linn)

+1y

You might be suprised at how much air those 5 piston rings will leak. Should work OK. Would be more concerned about the piston movement with to much grease though but then again you don't have an actual crankshaft so might be OK.

toddluck

+1y

looking very nice

Related Discussions in Mazda Projects

Thread

Posts

Last Post

852

last post by

skrapinsask +1y

150

last post by

cherokeed +1y