Street Source is shutting down April 30th, 2026. Read the announcement

Basement Workshop Build

baha

9 mo

After a long time of putting it off, I’m finally diving into the full rebuild of my workshop. It’s something I’ve wanted to do for a while—get things more organized, efficient, and better suited for fabrication and wrenching.

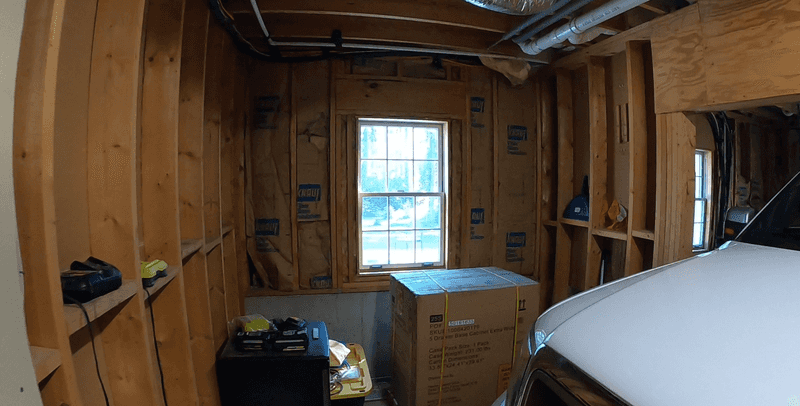

I started by ripping out all the old insulation and replacing it with Rock Wool, mainly for its soundproofing and fire-resistant qualities. It's already made a huge difference in comfort and acoustics.

While the walls were open, I took the chance to clean up and rework the electrical, adding more outlets where I actually need them (finally!), and prepping for better lighting down the road. I also sealed all the opening with expanding foam and added a new vapor barrier. It gets humid in GA summers, I hope all of this helps with the summer humidity.

Next came new paneling on the walls. It definitely made a difference in the area I've done so far. Since this is a workshop, I know the walls are going to get damaged, so I made it easy to replace.

The old fabrication table served its time, but it was overdue for an upgrade. I’ve replaced it with a new fabrication table and added a sturdy workbench alongside it. At some point I still want a larger fabrication table but can't justify the extra space it would take up for now.

There’s still a lot more to do—lighting, storage, maybe even epoxy flooring—but this is a solid start. I’ll keep updating this thread as I go.

If you’ve got tips or shop upgrades feel free to share.

I started by ripping out all the old insulation and replacing it with Rock Wool, mainly for its soundproofing and fire-resistant qualities. It's already made a huge difference in comfort and acoustics.

While the walls were open, I took the chance to clean up and rework the electrical, adding more outlets where I actually need them (finally!), and prepping for better lighting down the road. I also sealed all the opening with expanding foam and added a new vapor barrier. It gets humid in GA summers, I hope all of this helps with the summer humidity.

Next came new paneling on the walls. It definitely made a difference in the area I've done so far. Since this is a workshop, I know the walls are going to get damaged, so I made it easy to replace.

The old fabrication table served its time, but it was overdue for an upgrade. I’ve replaced it with a new fabrication table and added a sturdy workbench alongside it. At some point I still want a larger fabrication table but can't justify the extra space it would take up for now.

There’s still a lot more to do—lighting, storage, maybe even epoxy flooring—but this is a solid start. I’ll keep updating this thread as I go.

If you’ve got tips or shop upgrades feel free to share.

baha

9 mo

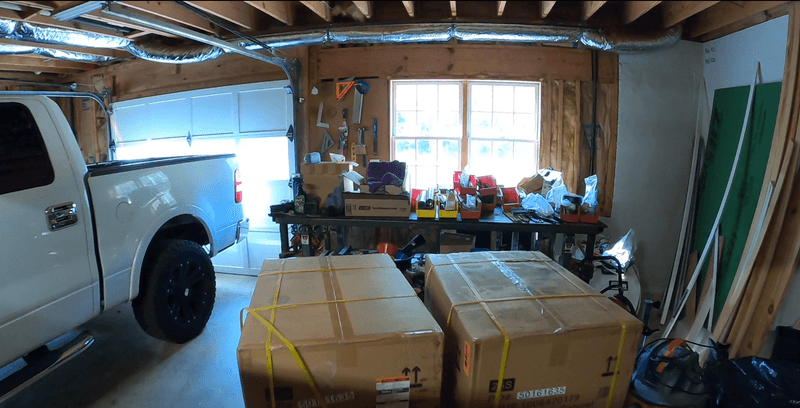

Here are some before pictures, I'll have to see if I can dig up some older ones when I first moved into this house.

You can see my old fabrication table in the background. I made it in my 20s to work on my body dropped Toyota project.....which I never finished. It's made out of a 4x8 1/2" thick plate steel for the top and 2x2 tubing for the leg and supports.

You can see my old fabrication table in the background. I made it in my 20s to work on my body dropped Toyota project.....which I never finished. It's made out of a 4x8 1/2" thick plate steel for the top and 2x2 tubing for the leg and supports.

baha

9 mo

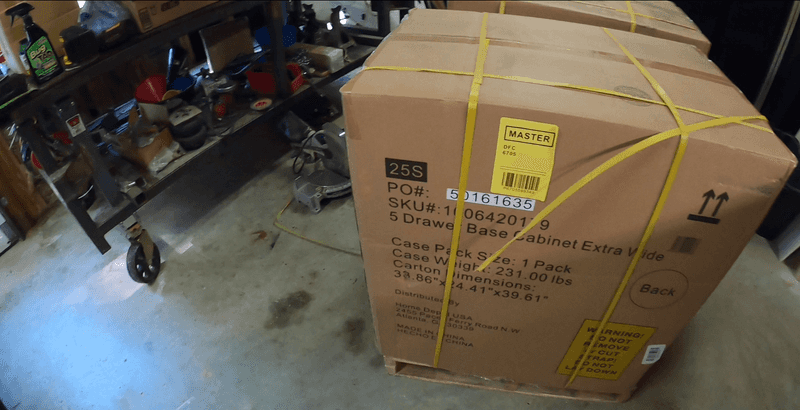

I have been a long time fan of the Husky line of tool cabinets at Home Depot, satin black with black handles, hard to go wrong right? I stumbled across this one size that is about 33 inches wide but it isn't always in stock. I figured 3 of these would be a perfect fit for the 8ft wall I have in the front left. I set up an alert on my phone and about 6 months later they had them in stock. I had to jump on it so that was really the first thing I bought for the build.

I've seen a lot of nightmares online where cabinets from Home Depot were damaged in shipping but I am happy to report that these survived. Now having said that though, I have definitely gotten a shipment from Home Depot that looked like it was sacrificed to a fork lift. I'm not sure why anyone would would even try to deliver something like that but I digress.

This reminds me, one time for my delivery confirmation, I got sent a picture of someone's lunch box that was sitting on the floor, guess he was proud.

I've seen a lot of nightmares online where cabinets from Home Depot were damaged in shipping but I am happy to report that these survived. Now having said that though, I have definitely gotten a shipment from Home Depot that looked like it was sacrificed to a fork lift. I'm not sure why anyone would would even try to deliver something like that but I digress.

This reminds me, one time for my delivery confirmation, I got sent a picture of someone's lunch box that was sitting on the floor, guess he was proud.

baha

9 mo

Here the cabinets are on casters. The casters that are designed for these fit very well, easy to install and move these around the shop. I'll post pics of more progress with them in their final location but this gives you an idea of what I was talking about. It came in handy to have them on casters so I could move them out of the way while I replaced the insulation and air sealed the walls.

baha

9 mo

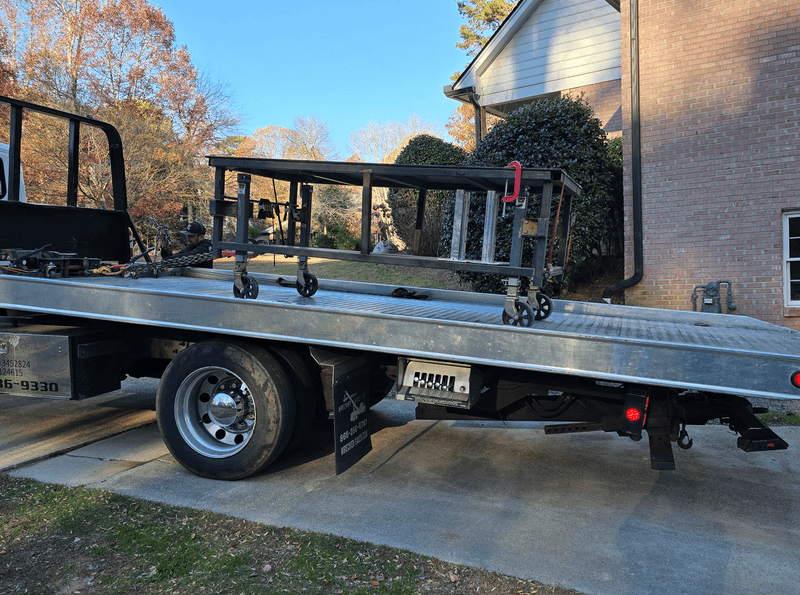

Here are some more pictures of my welding table before I sold it, it was very heavy duty! I built this in the 2010s, if only all of the fabrication tables were available back then!

I thought at some point I may want to have two tables side by side so I build it with the ends open on top for alignment. I used trailer jacks for the legs. I cut off the handles and welded on a nut so I could level it no matter where I rolled it. If I could go back in time, I would have used two fixed wheels, instead of all swivel. This table weighs over a thousand pounds easy, it's not the easiest thing to move around.

The final pic is of it going to it's new home!

I thought at some point I may want to have two tables side by side so I build it with the ends open on top for alignment. I used trailer jacks for the legs. I cut off the handles and welded on a nut so I could level it no matter where I rolled it. If I could go back in time, I would have used two fixed wheels, instead of all swivel. This table weighs over a thousand pounds easy, it's not the easiest thing to move around.

The final pic is of it going to it's new home!

Post was last edited on Jun 13, 2025 01:59. Edited 1

time.

baha

9 mo

I spent a long time looking at different options, I was even considering just using some saw horses and wood for when ever I needed something temporary but realistically I didn't have any up coming plans for a full blown fabrication table. I went back to Home Depot and found this work bench that can fold up so I figured it would be easy to move around. Also it does not have a 4x8 size top so it won't take up as much room.

There was some slight damage from shipping, but looked a lot worse from looking at the box. I figured it was a work bench after all so I know I will cause even more damage after it gets used.

There was some slight damage from shipping, but looked a lot worse from looking at the box. I figured it was a work bench after all so I know I will cause even more damage after it gets used.

baha

9 mo

And here it is fully unboxed and in it's new home.

baha

7 mo

Also picked up this new folding welding table, I am not expecting to do anything like a full frame build so this should be a good fit.

baha

7 mo

Also picked up this new toy, I have been wanting a multi process welder for awhile, just had to sell my old one first.

baha

7 mo

I don't have any in progress pics but I upgraded all my insulation and air sealed everything with foam. I still need to put up paneling but I am taking a break to work on some truck projects.

Related Discussions in Workspaces

Thread

Posts

Last Post

0

L

last post by

leon22 2 mo

32

last post by

baha 4 mo