Street Source is shutting down April 30th, 2026. Read the announcement

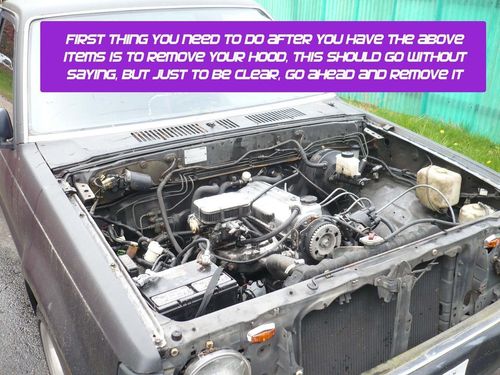

How To: Chevy 105amp 3wire Alternator Swap

Last Updated: Feb 24, 2015

Related Articles

1

1992 b2600i 4x4. Chevy 17 wheel custom fit center hubs

I could not find a write up on anyone doing a Chevy wheel swap onto a 4x4 so here it is. Wheels are...

H

How to: custom shifter boot

I thought i would make a thread about the shifter boot i made but although its really easy i wanted ...

How To Tighten Up Loose "Tow Mirrors"

This fix is for the members that have the "tow mirrors" or "large mirrors" on yo...

Suicide Hood Hinge How To, with complete captioned photos

Chris Frye and I decided to make a tech how to out of our hood hinge install day and we chose to ha...