Street Source is shutting down April 30th, 2026. Read the announcement

How To: Grinding Tabs for GM Wheels

Last Updated: Feb 24, 2015

OK, I read on here and was told by a friend what to do...I busted out the trusty old angle grinder this afternoon and started grinding....the following is what I used and some little tricks I learned in the process. this was my first tim doing this but its really not that bad a job.

This will allow you to mount GM 6 lug wheels on your Mazda without having to bore the center of the wheels, tools I used:

Hammer, goggles, ear plugs and the ninja Dewalt 4" angle grinder!

Obviously the goggles and ear plugs are optional but the grinding throws out LOTS of sparks that you can feel hitting your skin....I cam imagine how it would feel hitting your eye. Ear plugs....about 20 min into my first hub without them, my ears were ringing...im just glad I happened to have plugs in my tool box.

NOTE: I used one set of the stock lug nuts and put them on each wheel as I did my grinding...you do NOT want to hit even one of your studs with the grinding wheel so I stringly suggest you do as I did. I used the same 6 lugs throughout the entire job so that I didnt screw up all of my stock lug nuts.

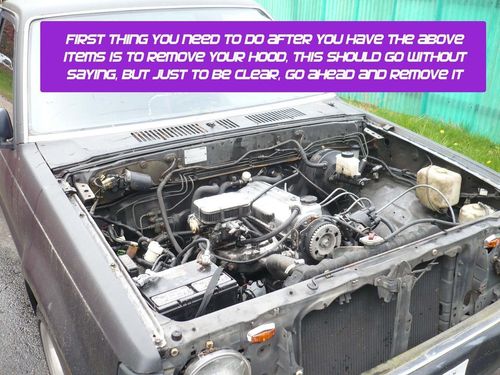

Here is the drivers side front hub, in the pic I have already ground down the left tab....the rest are still there.

You can grind with a grinding wheel all four tabs on the front hub in less than 10 minutes. Start with the TOP MOST tab ( and as you do each tab, rotate the hub so the next one is always at the top - this was the easiest way to do it IMO )

1. Place your grinding wheel on the BOTTOM side of the top tab, and start grinding , press forward a bit and up. What you are doing is getting the slightly wider base of the tab and also the majority of the width at once...honestly 30 seconds of grinding and your ready for the next step.

HERE is what you want to see after about 30 seconds...

2. Take that trusty hammer and hit that now weakened tab...it should break away with a couple solid hits and look like this:

3. Take your grinder and grind away the remaining little bit of tab, maybe a couple minutes MAX of grinding.

Once you have done the first tab, rotate the hub 1/4 turn, this will put the next tab at the top....repeat steps 1 - 3.

Here is what you will end up with:

Now to the rear......I must admit, the rear is more of a chore and my first one took me about 45 minutes of grinding.....but I AM HERE to give you the tricks that made the 2nd side take about 15 - 20 min max!

You can make this easier by having the rear of the truck jacked up so that you can rotate the rear hub.....I did not do this but it will make positioning the tabs for grinding a NICE perk.

Here is what you will start with....YES....two tabs are larger than the other two and ALL are larger than the front tabs!

I used a similar method as I did on the front hub tabs and this works for ALL rear tabs, regardless of size...

4. Set your grinding disk at an angle to the tab, start about in the middle of the tab and grind IN towards the thick base of the tab. What you are trying to do is turn that HUGE freakin tab into something similar to the front tabs. You want a THINNER tab than what is there....starting in around the middle and grinding in towards the base ( at an angle ) will provide a NICE ( thick as your grinding disk ) channel and this only takes a couple minutes....look at this pic and look closely at the right bottom most tab....see how its split almost in 2 by the grinder wheel? This is what you want!

5. Once you have this "channel" created, grind the now "not so thick" base all the way flush with the hub itself. Here is an example of what you will see when done, look now at the top most tab. See how the center most part is still there? That is ok....your GM wheel will more than clear this part. You are focusing mostly on the first 1/4 or so inch of the tab, this is what the GM wheel does not fit over.

6. Repeat for the remaining 3 tabs....should like about like this when done:

TEST FIT EACH WHEEL! Look closely and make sure the wheel is flush with the hub. When grinding your tabs, check them from the side and make sure they are ground all the way flush with the hub. ( the exception would be the inner parts of the rear hubs that you CAN leave in place if you want to.

NOW....MAKE SURE you use a lug nut that will SEAT properly in your new GM wheels. Chances are your Mazda lug nuts will NOT work. I made a trip to Autozone, bought a $30 set of 20 lugs. Size is 12mm x 1.5. Note that if you have access to some....OEM GMC Envoy Denali lug nuts are PERFECT. I stole one from a friends Envoy and tried it, also verifed the thread pattern at Autozone. You want a lug with a pretty LARGE \__/ shape. Use your best judgement here. I actually took one of my Yukon wheels with me to Autozone and they let me test fit a lug before purchase.

You will need to manually center your wheel on the studs as you SLOWLY hand screw on your lug nuts....this MIGHT not be a requirement but its what I did, it allows you to make sure your lug nuts are all centered on each wheel lug hole....I hope this part makes sense...just make sure you center the lugs on the wheels as you put them on.

And TA DA!!! The finished result...these are 2003 to 2007 Yukon wheels, 17"...or so I was told, LOL.

I used the black painted lug nuts from Autozone, I do not yet have center caps so these look ok. Also....since the kit only comes with 20 lug nuts....I am only running 5 on each wheel. I am going to check into ordering more or just getting a different set of lug nuts.

NOW....this was my first time doing this....if I was to do another truck right now....I imagine I could grind all the tabs off in less than an hour following the tips I provided above....by no means am I an expert on this and I welcome all feedback. I hope this helps those of you that have not yet had the opportunity to do this and had any questions...like me about 4 hours ago.

holla!

Credits

Created By: noridetoolow

Related Articles

How to: custom shifter boot

I thought i would make a thread about the shifter boot i made but although its really easy i wanted ...

How To: Chevy 105amp 3wire Alternator Swap

A.J. "SpaceMonkee" Demiar Bay Area, California 1992 B2200 (2.2 EFI) Standard Cab As t...

How To Tighten Up Loose "Tow Mirrors"

This fix is for the members that have the "tow mirrors" or "large mirrors" on yo...

Suicide Hood Hinge How To, with complete captioned photos

Chris Frye and I decided to make a tech how to out of our hood hinge install day and we chose to ha...