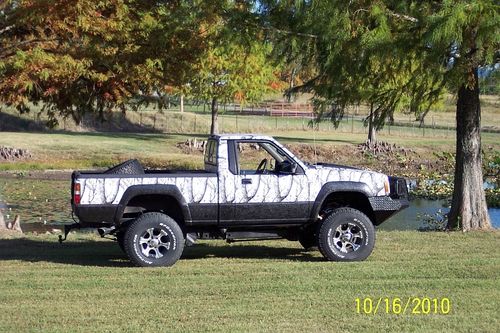

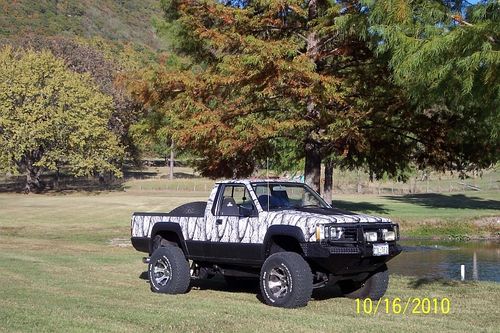

zach - 1993 Mitsubishi Mighty Max

A showcase of modifications and highlights of this ride.

General

- zach

- 1993 Mitsubishi Mighty Max

- Color: RealTree Hardwoods Snow

Ride Highlights

Engine

Ford 5.0 HO maf EFI - A9P EEC-IV, TRW forged pistons, Ford MotorSports cam & roller lifters, Accel ignition, BBK Headers w/FlowMaster exhaust.

Exterior

Schedule-40 Front Bumper & Tailgate, designed and assembled by ZACH. Bed, Floor Board, Bottom of Sides and Bumper done with HercuLiner. 100w CIBIE 175 lights. 4 inch Body Lift.

Interior

Ford Ranger seats, '90 Ford Bronco Dash Bezel and Guages. B&M shifter with Center Console designed and crafted on our shop.

Audio

Pioneer MP3

Suspension

Upper A arms lengthened 7/8" for proper camber adjustment. Ford Bronco rear sway bar. Energy Poly Bushings through-out. 5 inch suspension lift for a total of 9 inches.

Wheels

Dick Cepek 10x15's w/BFG 33x12.50x15 rubber

Other

Push button electric shift BW-1356 transfer case. Northern Hi-Perf. aluminum radiator w/2- 12" puller fans. Power Steering, Brakes and AC retained.

Future

An ongoing project!

Similar Mitsubishi Mighty Max Builds

droppedmitsus 1989 Mitsubishi Mighty Max

1989 Mitsubishi Mighty Max

joshhffmans 1991 Mitsubishi Mighty Max

1991 Mitsubishi Mighty Max

myd-maxs 1990 Mitsubishi Mighty Max

1990 Mitsubishi Mighty Max

ericbnch1982s 1992 Mitsubishi Mighty Max

1992 Mitsubishi Mighty Max